November 04, 2020

LED Towards the Light

We use LED lighting for our holiday installations, and you should too!

We use LED lighting for our holiday installations, and you should too!

The future is bright, mainly because the future uses LEDs for basically every lighting need. You may have heard about the general political movement to phase out the use of incandescent bulbs, and plenty of municipalities have been early adopters of the illustrious Light Emitting Diode.

LEDs have only been commercially available since 1968, which makes it a pretty young technology compared to incandescent lamps. Incandescents started replacing oil lamps and candles in the late 19th century, so needless to say, 160 years of innovation allows for one heck of an improvement. In our professional opinion, LEDs are better than incandescent bulbs in almost every imaginable way.

The Failings of Filaments

Incandescent light bulbs have been around a long time, sure. But they are far from ideal as light sources — in fact, they’re almost hilariously primitive by modern standards. If the aliens invaded today and landed in a chicken farm in Nebraska, they’d take one look at the henhouse lighting and zoom off back to Alpha Centauri because this civilization had obviously only just figured out how to rub two sticks together, and weren’t worth the aliens’ time.

Incandescent bulbs produce light by converting electricity into heat in a tungsten wire filament inside a glass bulb. So basically you’re making a tiny little fire inside an enclosure that will smash into a million razor-sharp pieces if you even look at it funny. What a spectacular and not at all hazardous idea!

The bulb protects the filament from oxidation, which is the chemical reaction that causes that filament to decay and eventually burn out. Because the bulb can’t be perfectly airtight, it is filled with an inert gas like nitrogen, krypton, xenon or argon to slow the oxidation process down. Much like applying wrinkle cream every morning, it just delays the inevitable.

The bulb protects the filament from oxidation, which is the chemical reaction that causes that filament to decay and eventually burn out. Because the bulb can’t be perfectly airtight, it is filled with an inert gas like nitrogen, krypton, xenon or argon to slow the oxidation process down. Much like applying wrinkle cream every morning, it just delays the inevitable.

Incandescent bulbs produce heat because that is the means by which they also produce light. If you’ve ever come too close to a lit Christmas tree on your way to the kitchen in 1995 while you weren’t wearing your ugly holiday sweater to shield your delicate flesh, you know that a hot incandescent mini light can singe your arm hairs just as badly as a fiery spark ejected from a Hawaiian volcano.

Sarcasm and hyperbole aside, incandescent lighting is inefficient, requires more energy, has a shorter lifespan, and lacks the versatility of LED lighting.

- Indicator and signage lighting

- Street and municipal lighting

- Decorative and residential lighting

- Automotive and airline cabin lighting

- Transmitting analog signals and data

- Barcode scanners

- Detecting biological agents using LEDs that emit UV light

The Strengths of Semiconductors

Sticking to LED lighting for commercial holiday applications just makes good business sense. Here’s why, and why you too should embrace this bright and shiny future for any of your lighting needs, festive or otherwise.

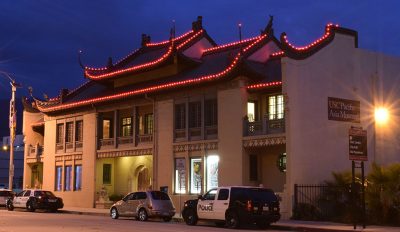

- Since switching to C9 LED bulbs for our clients, our building lighting maintenance has become much quicker and easier. Incandescent C9s burn out and break at an alarming rate, especially when they’re installed on a light line that has to be hoisted up to the top of a building on an aerial lift and moved around by work crews at 4 in the morning. C9 LEDs have shatterproof polycarbonate bulbs that don’t break even if you run a 19,000 lb truck over them. We know, because we’ve done it!

- C9 LEDs come in the same colors as incandescents, with the added advantage that (in non-commercial light strings, at least), the plastic bulb can sometimes be removed and then replaced on a different diode. One of our staff members has experimented with this herself, achieving a lovely shade of teal by screwing a dark blue bulb onto a green diode.

- LED lighting dramatically reduces energy costs for our clients. It’s why we recommend retrofitting parking lot lighting too – LED light pole fixtures are brighter, need little to no maintenance, come with an excellent warranty (we use only reputable brands, which offer warranties lasting 1 to 10 years), and use about 75% less energy than an incandescent or HID (high-intensity discharge) lamp.

- The versatility of LEDs and DMX controllers can turn any outdoor lighting display into a gigantic, shining work of art! If you want your lights to twinkle, you got it! If you want them to chase and change colors, we can make it happen! You want a huge grid of LEDs that can be used as a canvas for patterns the likes of which no human (or alien) has ever seen? We might have to ask the Alpha Centaurians for some artistic input, but believe it or not, it is an achievable goal!

Moral of the story: don’t fear the LED! Technology is a wonderful thing that comes with both commercial and personal benefits. May your holidays this year shine brightly, and may your arm hairs remain unburnt!

| A Field Guide to Holiday LEDs | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

There are a few different shapes and sizes of commercial holiday LED bulb that we use, and their names aren’t always descriptive. Here’s a handy quick-reference guide.

|