October 7, 2020

The Santa Ana winds are coming – are you prepared for the fallout?

The Santa Ana winds are coming – are you prepared for the fallout?

Ultrasonic testing is a crucial step to take before you complete your LED retrofit or light pole banner advertising campaign. Why is that, you ask? Well, because light poles can fall down. Obviously, drivers who are too busy texting to pay attention and delivery truck operators with less-than-stellar depth perception can cause these failures, but the most pressing concern is corrosion.

Light poles in commercial and public parking lots are 100% metal. Metal corrodes and decays, especially when exposed to the elements for years, taken for granted and rarely maintained. Property managers and municipalities usually have their eyes glued more to their budgets and pole painting schedules than they do to issues of structural integrity.

Light poles are engineered structures that support single or multiple light fixtures along with banners, signs, hanging pots or other accents. They also tend to accumulate birds, their waste, snow, and lots of stickers. Most are made of aluminum or steel, and are rated using a metric called an EPA (effective project area), which is determined by the square footage of the profile and its ability to withstand high winds. Most poles are rated at 80, 90 and up to 110 mph winds.

If a light pole falls in the woods…

There are plenty of reasons a light pole might fail. Here are a few examples:

- Vibration by wind and even light or moderate vehicle impacts cause stress to poles that accumulates over time.

- If the pole is located right next to a sprinkler head and gets bombarded with moisture for several hours a week, that can lead to excessive corrosion.

- Sometimes Mother Nature decides to go ham with the elements. While she might dump water in various forms all over other states, she spends the Southern California autumn playing ping pong with our garbage cans using the Santa Ana winds as a paddle. Walking outside feels like getting blasted by a hairdryer the size of a cruise ship. You try standing up straight after a few days of that kind of sustained buffeting.

- A pole with a large banner installed on it is at even greater risk – if that banner is in a high-wind area, it acts like a sail, pulling the pole in whichever direction the wind catches it. Wind slits cut into a banner provide a false sense of security, as in our experience, they really don’t work.

Fallen light poles can be prevented. While vibration, wind, and the elements take their toll over time, staying on top of a light pole’s condition is less complicated than it may seem.

A little background

Ultrasonic pole testing really works well on steel and aluminum poles. Some intensive training about 10 years ago with a Level III Nondestructive testing expert gave us the toolkit we need to help our property managers. There is a whole American Society of Nondestructive Testing (NDT LIII) program certification that’s geared toward engineers.

Used for testing flaws in things like bridges, overpasses and structural support columns, it includes radiography, neutron radiography, magnetic particle testing and a slew of other intimidating multisyllabic words that thankfully do not apply to preventing the collapse of your garden-variety parking lot light pole. It turned out that very few companies offered this valuable service, and the ones we researched did not have any training whatsoever, so it made sense to go the extra mile.

Used for testing flaws in things like bridges, overpasses and structural support columns, it includes radiography, neutron radiography, magnetic particle testing and a slew of other intimidating multisyllabic words that thankfully do not apply to preventing the collapse of your garden-variety parking lot light pole. It turned out that very few companies offered this valuable service, and the ones we researched did not have any training whatsoever, so it made sense to go the extra mile.

We employ some basic techniques that give us the most accurate picture of how well the poles are holding up:

- Visual inspection: photo, catalogue and note any rust

- Ultrasonic wand on 4 planes: measures wall thickness at stress points

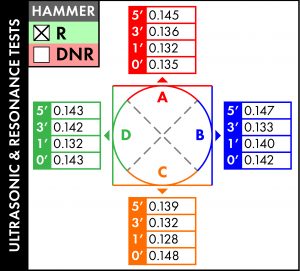

- “Hammer” or resonance test: produces a sharp ping (solid metal) or dull-sounding thump (rust)

- Base plate measure and torque bolt nuts: checks to see if the hardware attaching the pole to the pedestal is secure

| The Benefits of Pole Testing |

|---|

It’s not just about preventing your poles from falling, although they do tend not to work so well if they’re lying on the ground.

|

How to prevent fallen poles

Most problems are identified by the visual, resonance and base plate portions of our testing. The hammer test involves tapping the sides of the pole with a steel hammer for resonance. When you don’t get an echo or “ping” back, that’s usually because of corrosion. It’s the equivalent of tapping a hammer on a tuning fork, versus tapping a hammer on pile of fresh soil.

What makes the ultrasonic portion unique is the fact that it allows us to see damage on the inside that’s invisible from the outside. Using an ultrasonic gauge, we look for deviations in the wall thickness across different planes. Most of these deviations are due to paint and powder coat thickness. An 11-gauge steel pole is .125” thick.

We often see data showing thicknesses from .129 to as high as .160, resulting from any powder coating and pole painting conducted over the years. What we really watch for is a pole with a small caisson located adjacent to a sprinkler and/or enveloped by trees. These are the ones exposed to excess moisture, and therefore the ones most prone to rusting.

When we see significant deviations between upper and lower measurements on any of the 4 planes, we take additional measurements from the base at 0 inches, up the pole by 12 inches, up 36 inches, and then at 60 inches. We place the probe away from the rusted spots to confirm our conclusion. Measurements are taken on all four sides of the pole. Square poles are easily partitioned by sides, and we visually separate the round poles into 4 quarters.

When we see significant deviations between upper and lower measurements on any of the 4 planes, we take additional measurements from the base at 0 inches, up the pole by 12 inches, up 36 inches, and then at 60 inches. We place the probe away from the rusted spots to confirm our conclusion. Measurements are taken on all four sides of the pole. Square poles are easily partitioned by sides, and we visually separate the round poles into 4 quarters.

A conventional ultrasonic gauge that measures the total thickness of painted metal will erroneously measure the paint layer at the sound velocity of steel, typically increasing the apparent metal thickness by more than twice the thickness of the paint, due to the paint’s much slower sound velocity.

There are testers costing upwards of $3,500, but they are a little overkill for checking light pole thicknesses. We’re not in the habit of using a circular saw to cut the crusts off a sandwich. Our device of choice: the NDT Systems TG110-DL, which has a feature that allows us to determine paint thicknesses. We can examine every inch of the pole by sliding the probe across any questionable areas, and it hasn’t steered us wrong yet.

Test your poles, and rest easy!

When investing in new LED fixtures or even hanging pole banners, ultrasonic pole testing is highly recommended. You might also want to submit the report to your insurance, as it’s an excellent preventative maintenance measure and reduces your liability.

Comprehensive service is our goal – our clients end up with a detailed testing report and a map of their pole locations. We even tighten the anchor bolt nuts if they’re loose. If a pole needs replacing, we specify replacements that are “hot dip” galvanized on the inside at the factory for maximum corrosion protection and pole lifespan. Re-test your poles every two years (more if you get a lot of wind), and you’re pretty much golden.